San Juan County Historical Society Museum

The Mining Heritage Center and 1902 County Jail Museum are operated by the San Juan Historical Society. The museums are located at 1557 Greene Street next to the County Courthouse in Silverton. The museums are open from the end of May through mid-October. The mining museum covers every aspect of hard rock mining, and the jail museum offers a snapshot of crime, justice, and everyday life in the early 20th century.

1902 San Juan County Jail Museum

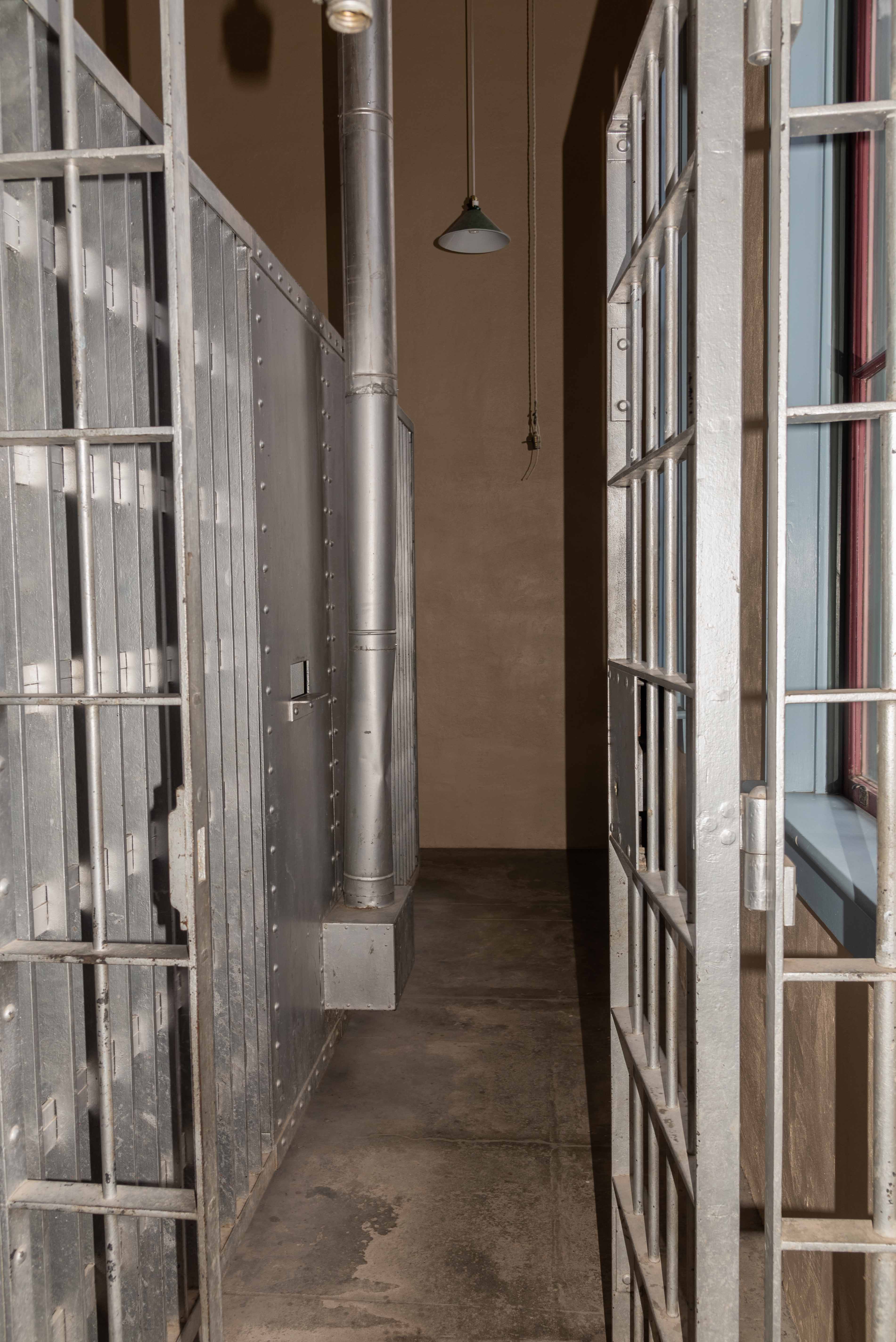

The 1902 jail was the fifth jail built in Silverton and the first county jail, the

previous four being "City Jails". The cell blocks and security doors were constructed by

the Pauly Jail Building Company in Indiana and shipped to Silverton as a "kit". The main

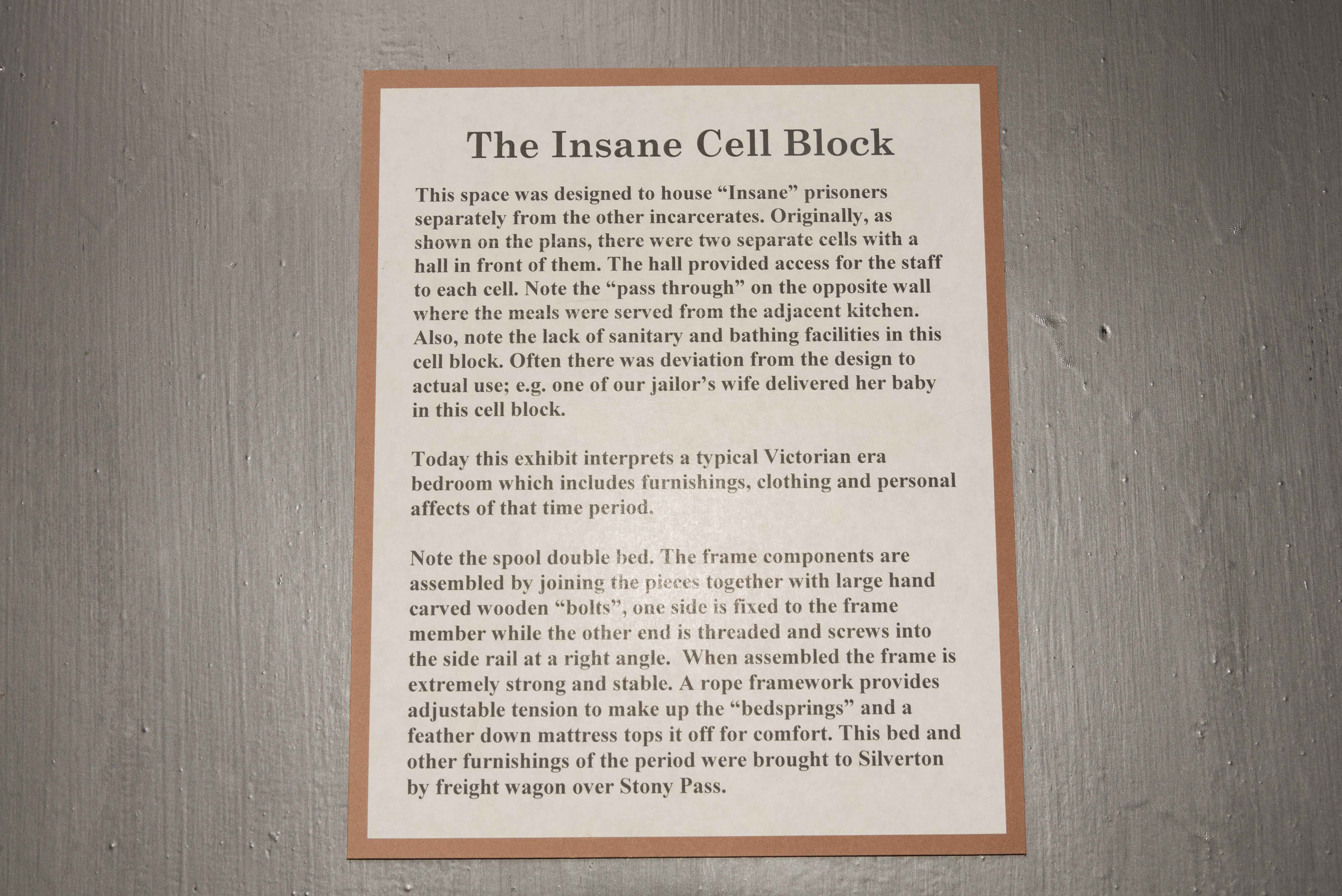

cell block of four cells is located on the second floor, and there are two cells on the

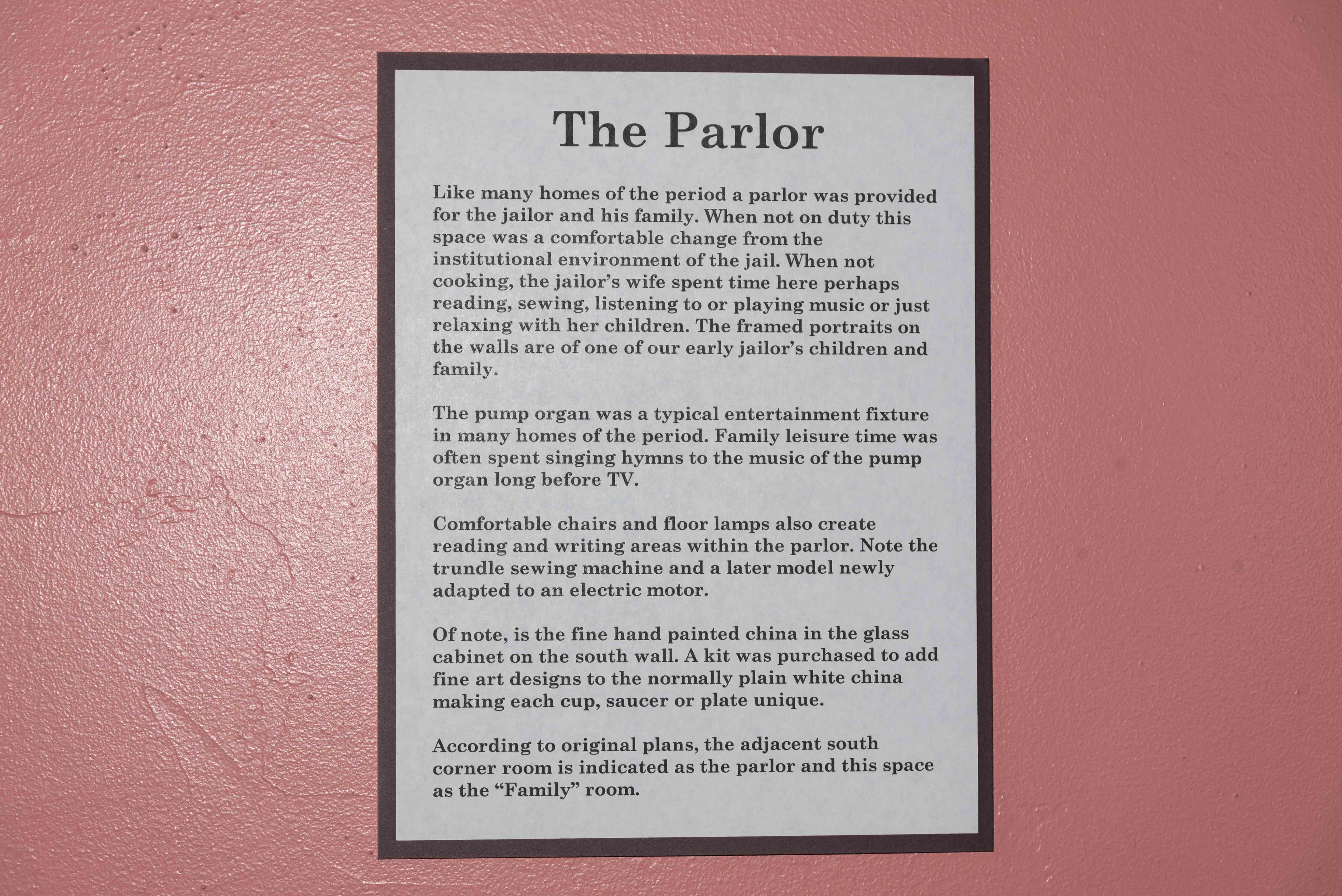

first floor to house women or "insane" prisoners. The jail also contained living quarters

for the jailer and family.

San Juan Historical Society Mining Heritage Center

The Mining Heritage Center is all about the mining industry, particularly in Colorado. The museum's displays

and exhibits cover most every aspect of hard rock mining: exploration, mining techniques, equipment, refining,

safety, and much more. Everything you ever wanted to know about mining can be found in this fascinating museum.

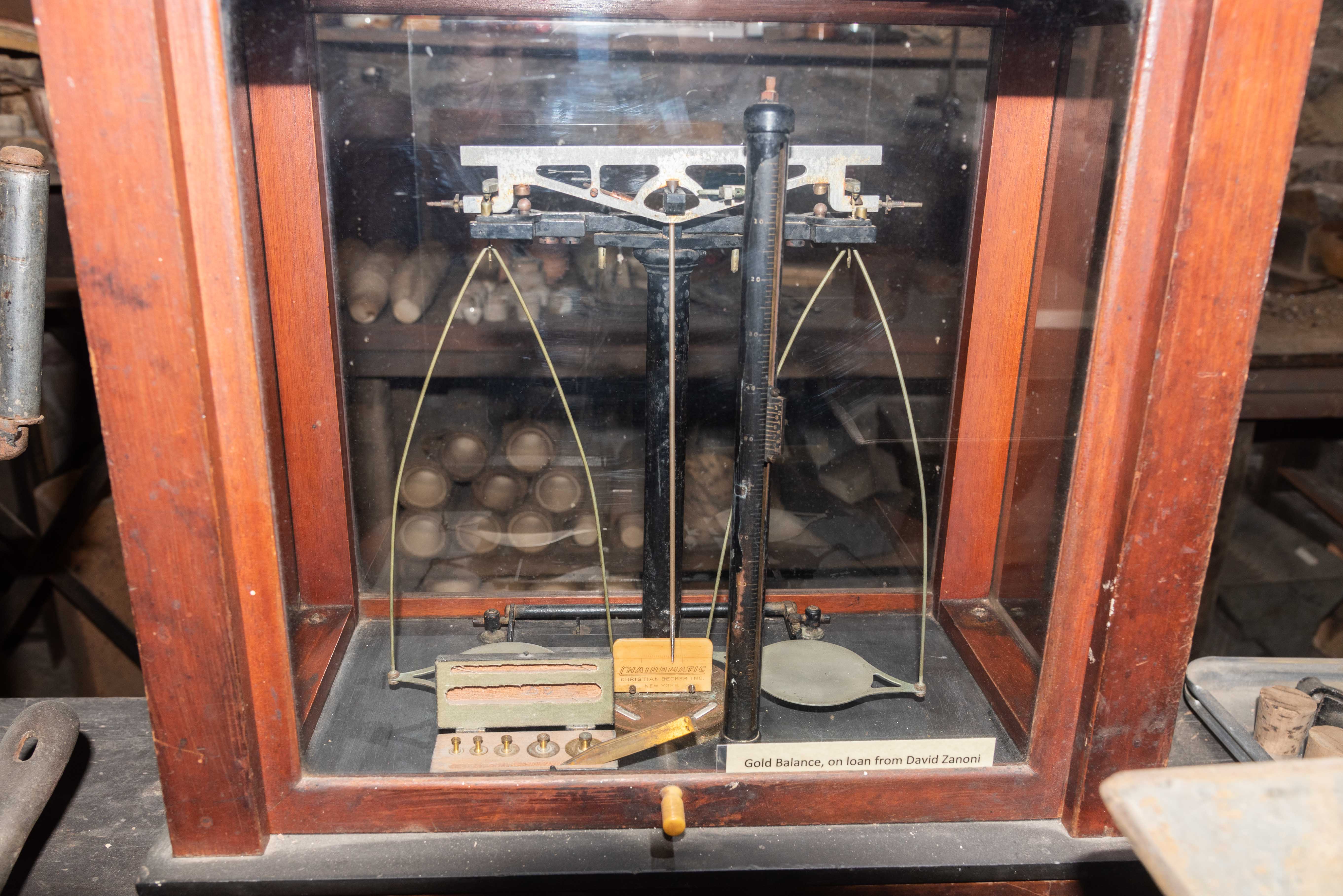

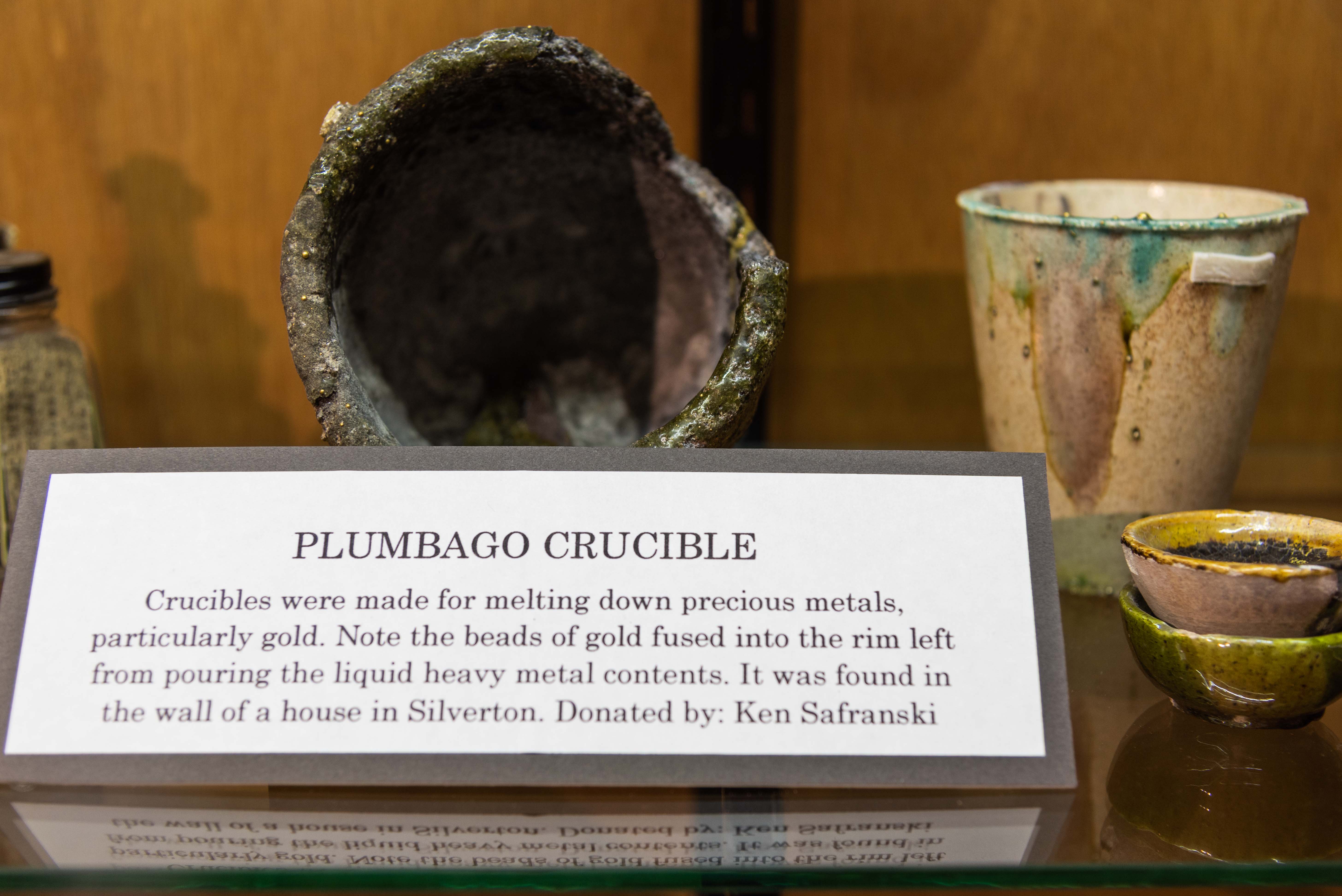

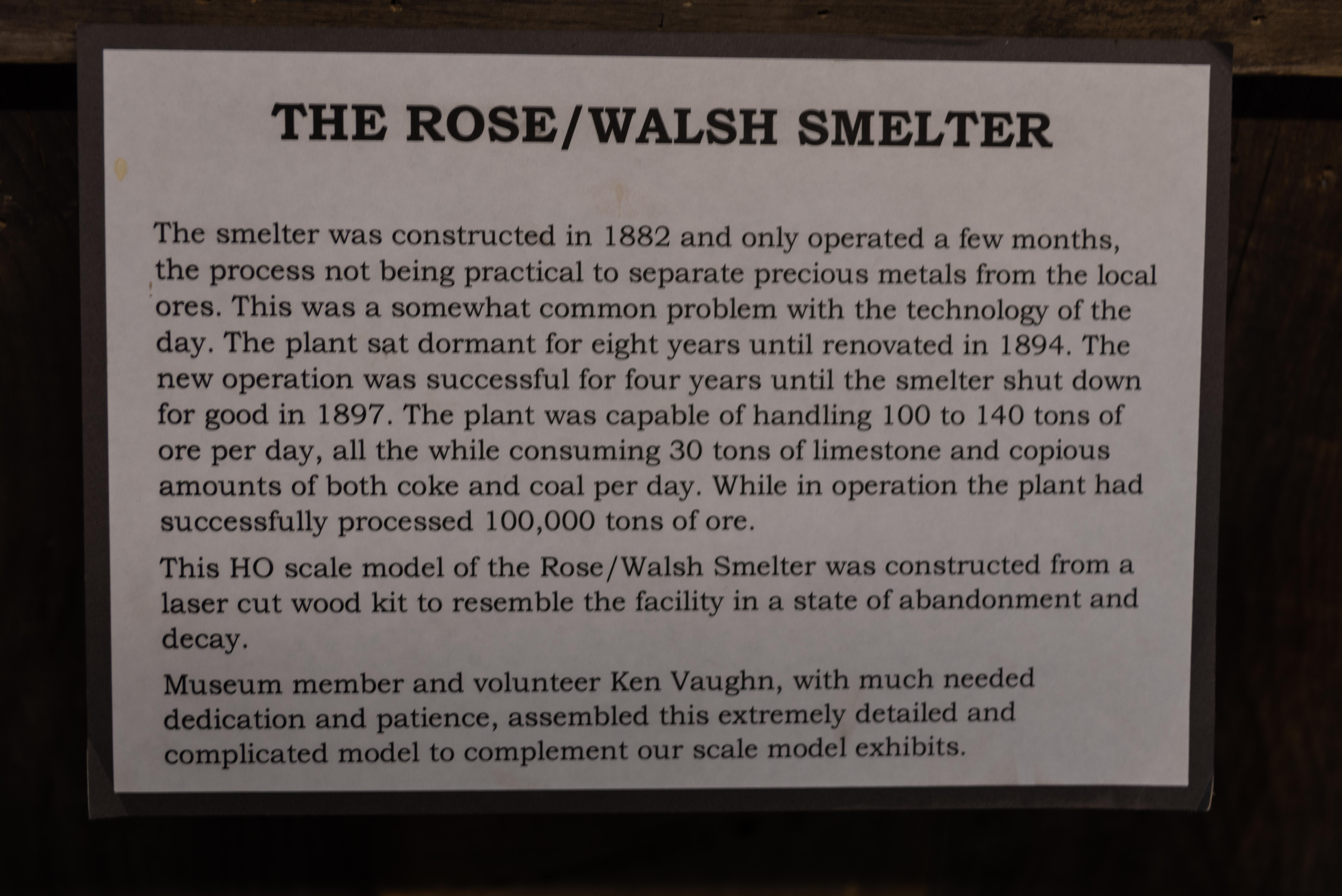

Metallurgy Assay Lab - Assaying of ores is divided into two general classes: fire assays for precious metals such as gold and silver, and wet, or chemical assays for other metals such as copper, lead, zinc, and iron. Most assayers in the early mining camps were usually assaying for only gold or silver. As mines started producing ores of copper, zinc, and lead, more complete metallurical assay labs were needed that could asssay for these metals, in addition to silver and gold.

Lots of minerals - The museum houses several donated mineral collections.

The photos in this section are a sampling of the dozens of exhibits in the museum.

A few words about tommyknockers - Most of the miners in the late 19th and early 20th centuries were

European immigrants, and the most sought after were the miners from Cornwall, England.

It seems that many Cornish miners had cousins named Jack, and they eventually became

known as "Cousin Jacks". They brought with them their superstitions of "tommyknockers".

Tommyknockers were gnomes, similar to Irish leprechauns, who dressed in miners' outfits

and dwelled underground. They were thought to be both good and bad. Hammering

by tommyknockers was believed to be the source of the knocking sounds that often

preceded cave-ins.

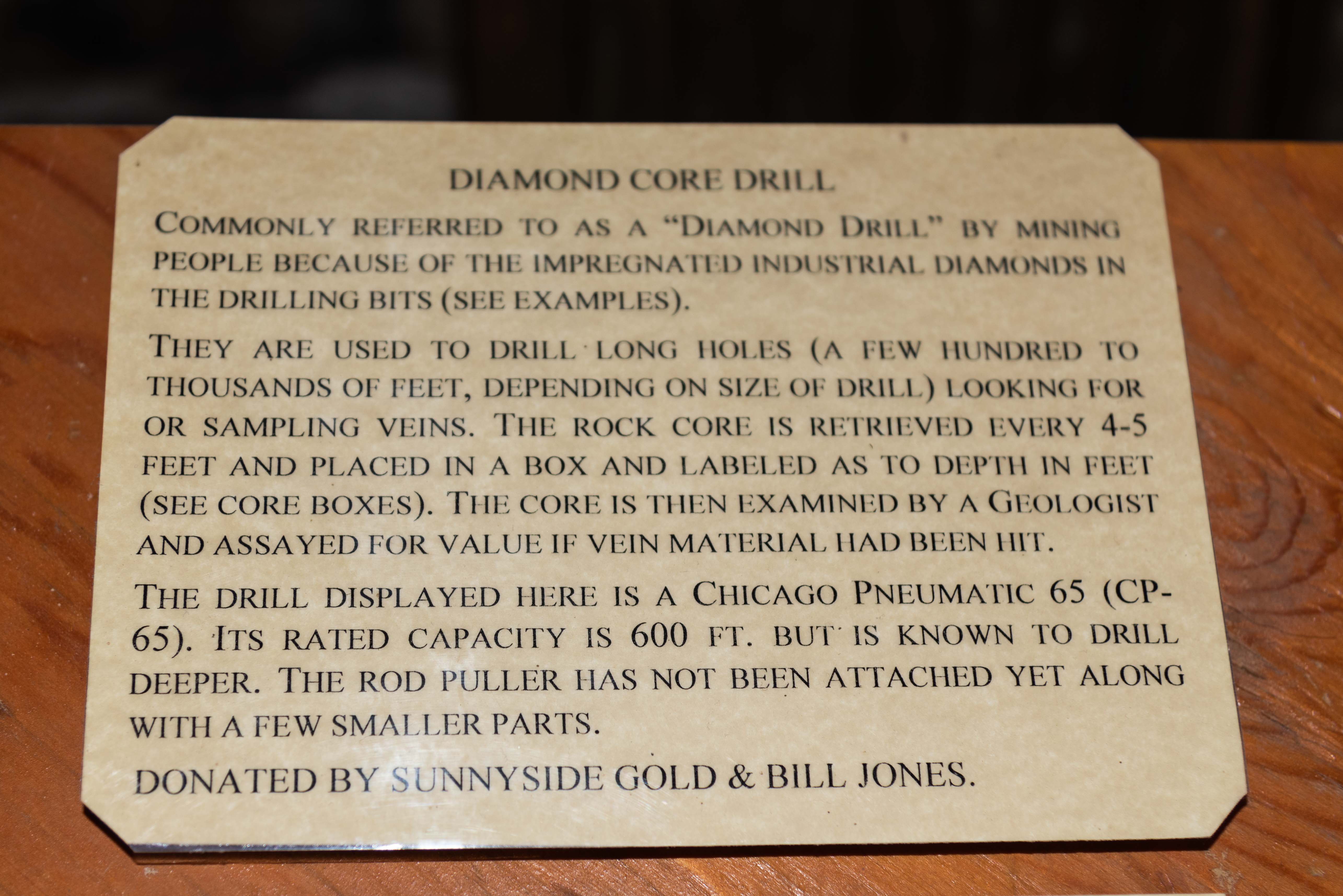

Diamond Core Drill - Core drills were used to probe known ore deposits or search for new ones. Cores from a few hundred to several thousand feet were drilled. The core samples were recovered and examined by geologists to determine whether to begin, continue, or abandon a mine. Prior to the availability of diamond core drills, most mineral prospecting consisted of finding surface outcrops or hand digging.

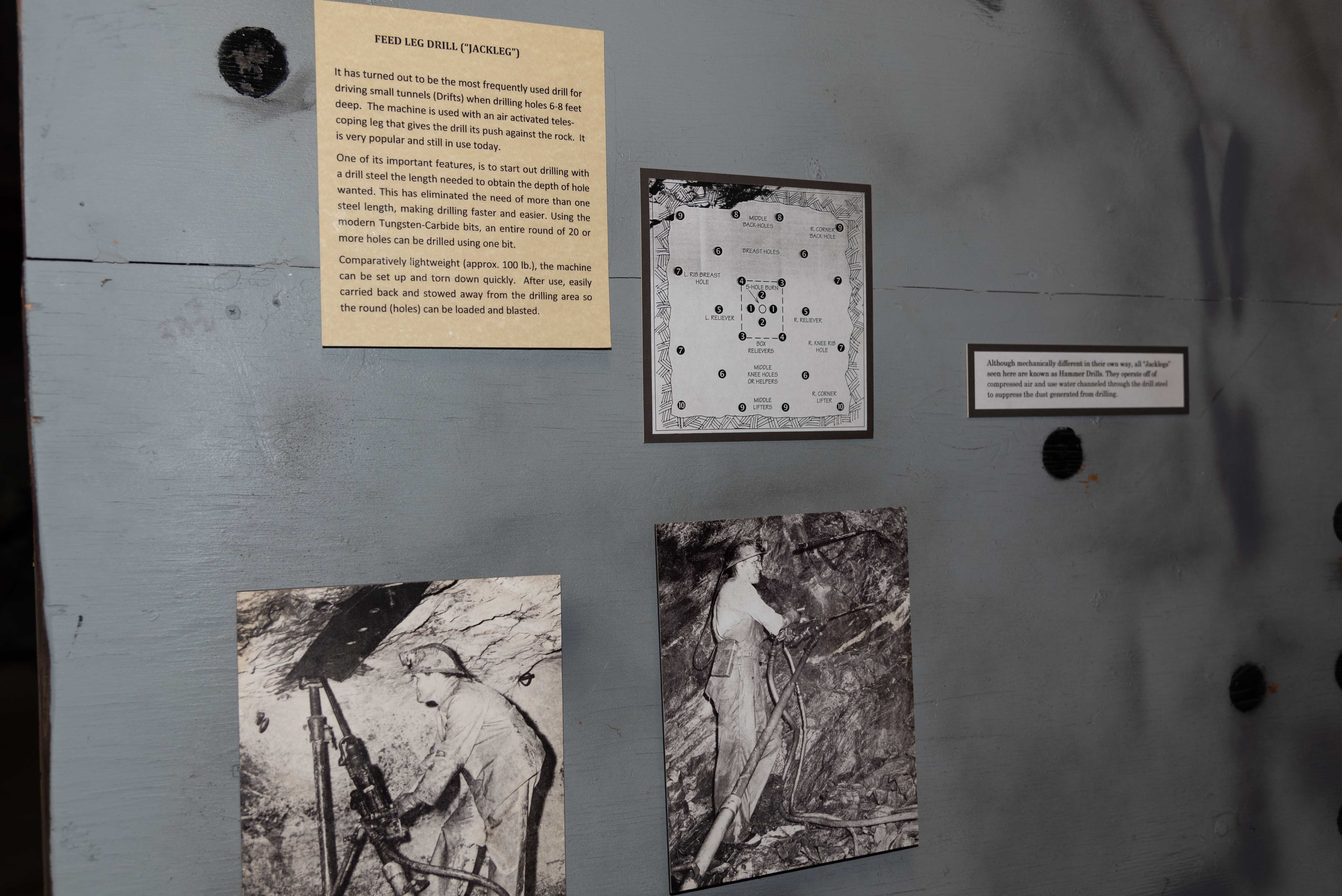

Mining Drills - Holes for placing dynamite charges were drilled by hand in the early days of

hard rock mining. A drill steel would be repetitively struck with a hammer, gradually driving it into

the rock face creating a hole. The steel was rotated an eighth to quarter turn after each strike. One miner

using both hammer and steel was "single jacking". "Double jacking" involved a pair of miners, one turning

the steel and the other using the hammer.

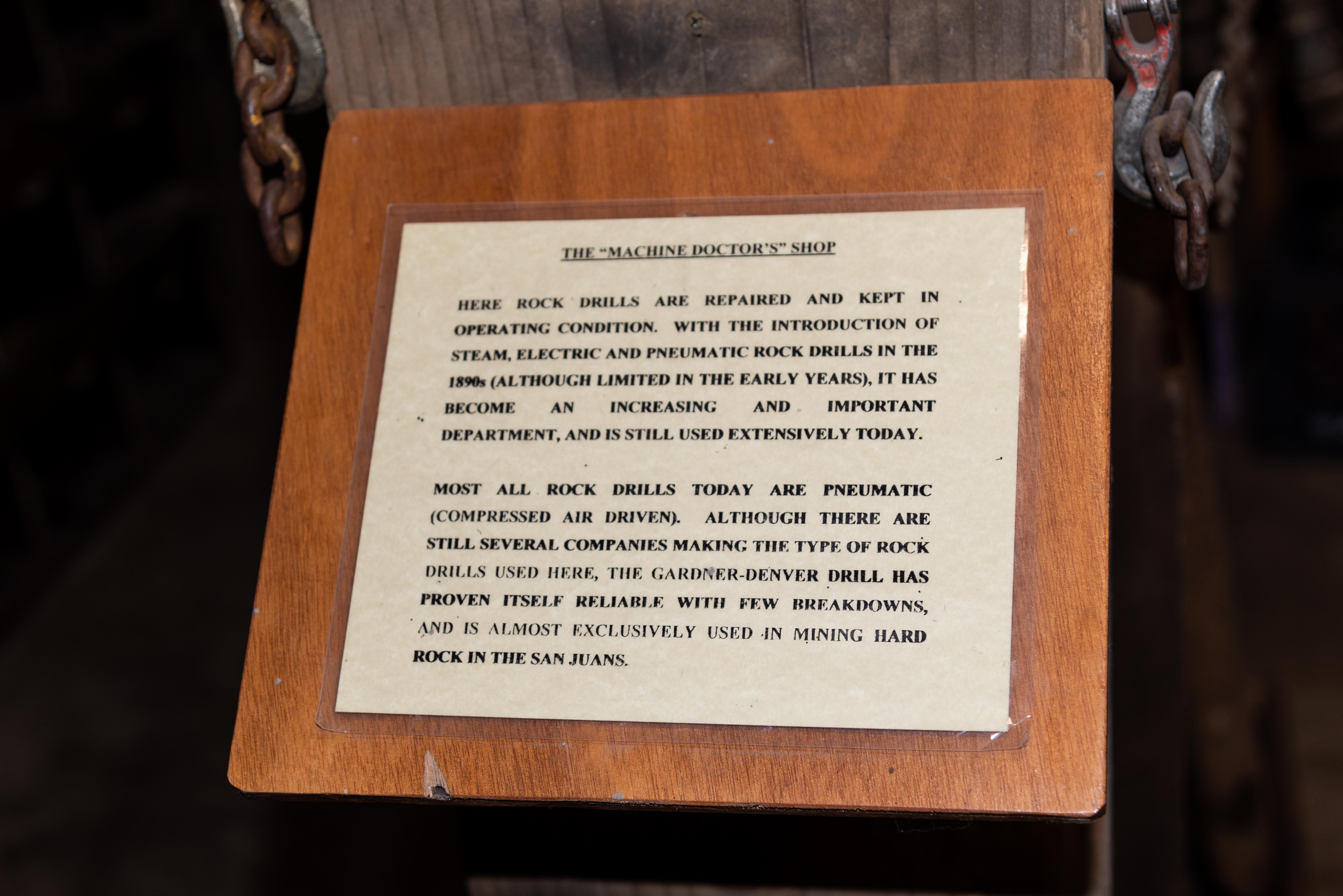

The introduction of pneumatic drills dramatically improved

hard rock drilling. Pneumatic drills served different purposes. Stoper drills were used for up-hole or overhead drilling.

Sinker drills were used for down-hole or shaft sinking. Drifter drills were used in driving tunnels (drifts).

Jacklegs are fairly lightweight pneumatic drills that are attached to telescoping legs, which push the drill

for the operator. Jacklegs can drill in all directions and are often used in lieu of drifters and stopers.

Early pneumatic drills created large amounts of fine silica dust. Chronic inhalation of the dust caused the pathological

condition of silicosis or Miner's Consumption (Miner's Con). Silicosis caused the deaths of thousands

of miners in the early days of hard rock mining, and earned the drills the nickname, "widow makers".

Water lines were eventually added to the drills to suppress the dust.

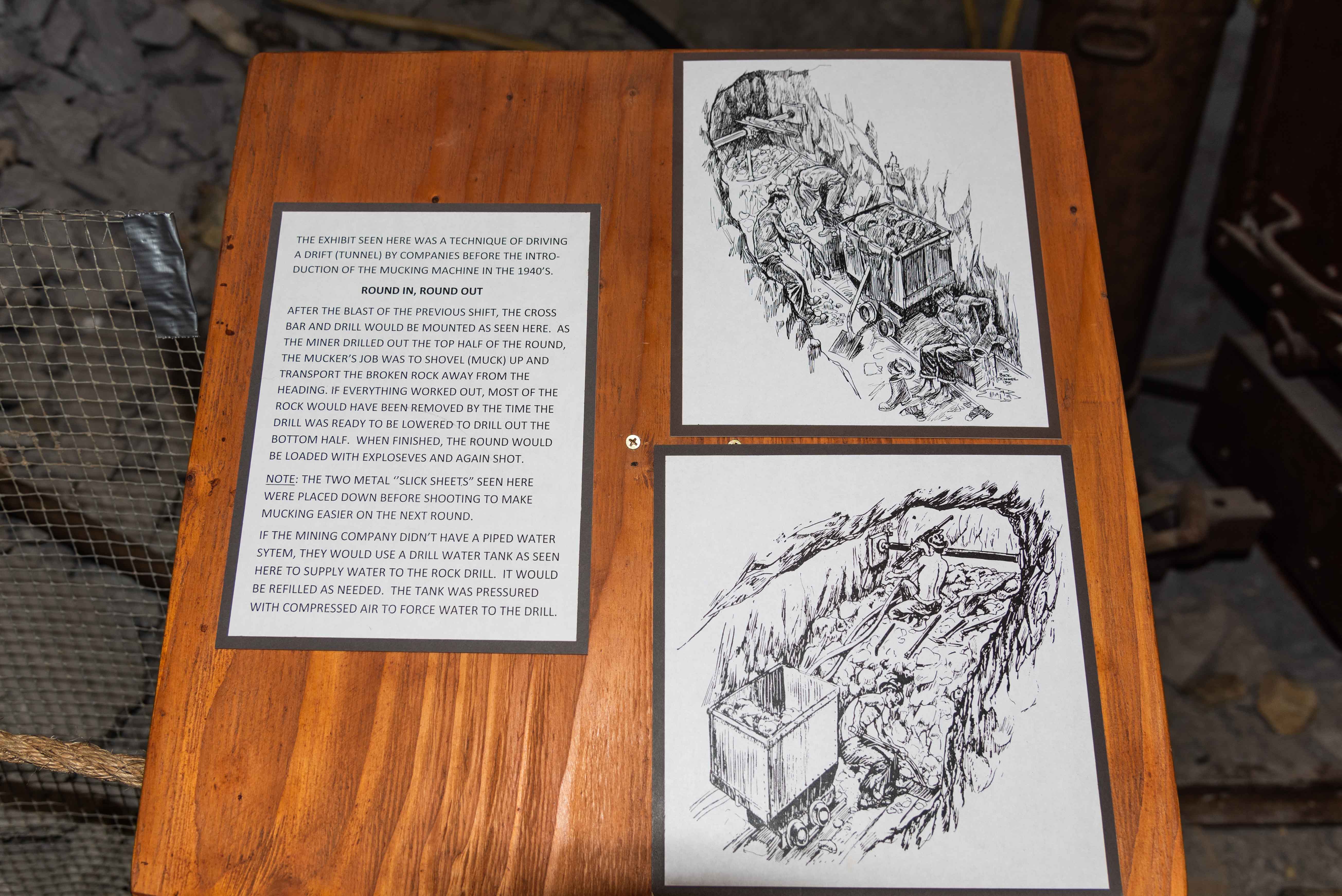

Holes were drilled in a specific pattern in the face of a drift or stope. Dynamite was inserted into the holes and fired to break up the rock and advance the drift. The blasted ore and waste rock was loaded into carts for removal to the surface. This process was called "mucking" and was done manually by human muckers or by mucking machines.

The mined ore was transported to mills and smelters in ore wagons, railroad cars,

or by tramline, depending on the location of the mine.

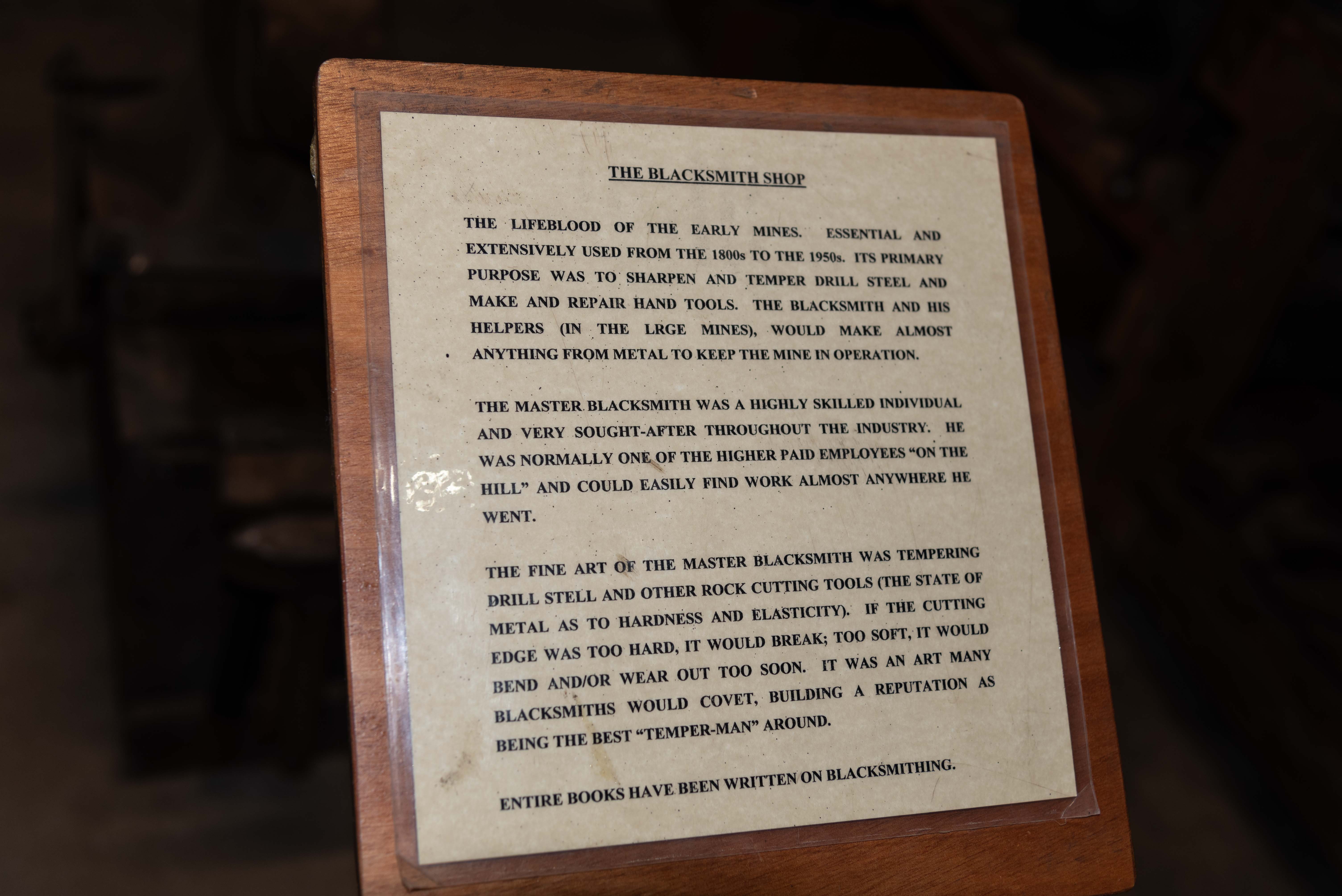

Mines were supported by dozens of workers and tradesmen. Lumbermen and carpenters provided

the timbers that supported the stopes and drifts. Blacksmiths sharpened drill steel and repaired

tools and equipment. Machinists maintained the mucking machines and locomotives that

pulled the ore carts. Mule skinners and railroad men transported ore, and cooks and maids

staffed the boarding houses where the miners stayed.

Background sources: Wikipedia, sanjuancountyhistoricalsociety.org, legendsofamerica.com

Use the form on the Home Page to submit comments, questions, or suggestions. TD Productions Copyright © 2021